Hongchen

Key words:

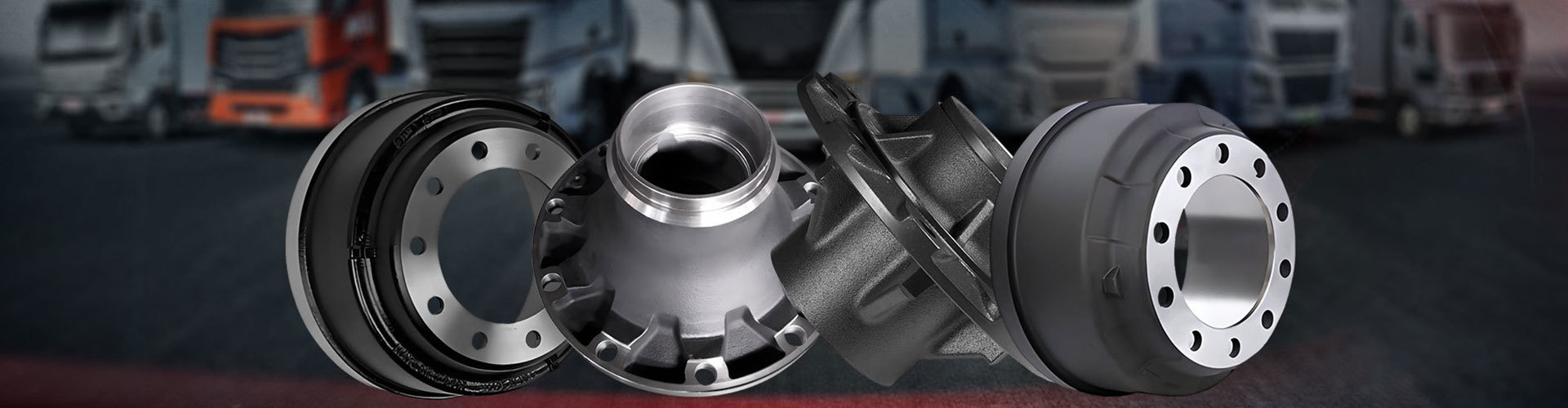

The brake drum is a cast iron part shaped like a tambourine, which is fixed with the tire and rotates at the same speed. When braking, hydraulic pressure is used to push the brake shoes (Brake Shoes) to contact the inner edge of the brake drum, and the friction force generated by the contact is used to suppress the rotation of the tire to achieve the purpose of braking.

Key words:

The brake drum is a cast iron part shaped like a tambourine, which is fixed with the tire and rotates at the same speed. When braking, hydraulic pressure is used to push the brake shoes (Brake Shoes) to contact the inner edge of the brake drum, and the friction force generated by the contact is used to suppress the rotation of the tire to achieve the purpose of braking.

Key words:

The brake drum is a cast iron part shaped like a tambourine, which is fixed with the tire and rotates at the same speed. When braking, hydraulic pressure is used to push the brake shoes (Brake Shoes) to contact the inner edge of the brake drum, and the friction force generated by the contact is used to suppress the rotation of the tire to achieve the purpose of braking.

Key words:

The brake drum is a cast iron part shaped like a tambourine, which is fixed with the tire and rotates at the same speed. When braking, hydraulic pressure is used to push the brake shoes (Brake Shoes) to contact the inner edge of the brake drum, and the friction force generated by the contact is used to suppress the rotation of the tire to achieve the purpose of braking.

Key words:

Brake drum design requirements

Improper design of the brake drum, easy to change when heated; unbalanced force of the brake drum will also produce mechanical deformation, which will cause poor contact between the shoe and the drum, resulting in increased pedal force and stroke; when the working surface of the brake drum is too large, it will also cause self-locking and produce vibration and noise. Therefore, the brake drum should have sufficient wall thickness, and the outer surface near the opening part of the cast circumferential or axial reinforcement to improve strength. These stiffeners also play the role of heat dissipation, which can reduce the temperature of the friction surface, shorten the cooling time of the brake, and increase the energy capacity by 35% to 40%.

Key words:

The working principle of the brake drum

When the brake is applied, the brake drum will stop rotating, thereby slowing the car. During the braking process, the brake will transmit the braking force to the brake drum, causing the brake drum to generate friction, thereby converting the kinetic energy of the car into heat energy, and finally realizing the deceleration and parking of the car.

Key words:

In order to maintain the normal operation and service life of the brake drum, regular maintenance and maintenance are required. Including checking the brake drum for cracks, wear and dirt, etc., and timely repair and cleaning. In addition, it is necessary to regularly check the lubrication of the bearings and maintain sufficient lubricating oil. If the brake drum is found to be abnormal, it should be replaced in time.

Key words:

Quality requirements of gray cast iron for brake drum

Generally speaking, gray cast iron is a suitable material for the manufacture of brake drums, but due to the extremely harsh working conditions of the brake drum, there must be some special requirements for the gray cast iron used.

Key words:

What is the difference between a wheel hub and a brake drum?

Wheel hub: Wheel hub is also called rim, wheel cover, and wheel hub. The shape of the tire supported by the inner contour of the tire is a barrel shape. The metal part in the center is installed on the shaft. The wheel hub is different according to the diameter, length and width, and the forming method is different., The use of different materials is divided into many different types. In terms of classification, it can be roughly divided into two types: baking paint and electroplating. When choosing wheels, ordinary models mainly consider whether the heat dissipation is good, and do not pay much attention to the appearance. The process is basically processed by baking paint, that is, spraying and electric baking first, and the cost is relatively economical., Beautiful color, long storage time. Brake drum: The brake drum is the friction pair of the drum brake in the drum brake system. It has a high and stable friction coefficient, appropriate wear resistance, heat resistance, heat dissipation and heat capacity, and relatively high strength And stiffness, but it will become brittle after aging. The brake drum is an important part of the drum brake, similar to the brake disc in the disc brake. When braking, the piston applies pressure to the two half-moon shoes to make them lean against the inner wall of the tympanic chamber, thereby generating friction to stop the rotation of the wheel.

Key words:

What is the material of the brake drum?

The brake drum is a cast iron piece similar to a tambourine that is fixed to the tire and rotates at the same speed. When braking, the oil pressure is used to push the brake shoe to contact the inner edge of the brake drum, and the friction generated by the contact is used to suppress the rotation of the tire to achieve the purpose of braking. The drum brake is composed of a brake base plate, a brake wheel cylinder, a brake shoe and other related connecting rods, springs, pins and a brake drum. At present, it is only used on the rear wheel. Drum brakes have low cost and high absolute braking force, and are widely used in the rear wheels of small cars. However, its wear rate is high, so the overall cost is high.

Key words:

How to choose a suitable for you?

Let us assist you!

Our experts will contact you as soon as possible to meet your needs.

Latest Products

Latest News