Understanding Truck Brake Drums: Essential Insights for Professionals in the Automotive Industry

Release time:

26 Jul,2025

Truck brake drums are pivotal components in heavy-duty vehicle braking systems, playing a crucial role in ensuring safe and effective stopping power. As a professional in the automotive and parts industry, understanding the intricacies of brake drums can significantly enhance your service quality and customer satisfaction. Brake drums function by using friction to slow down the vehicle. When the

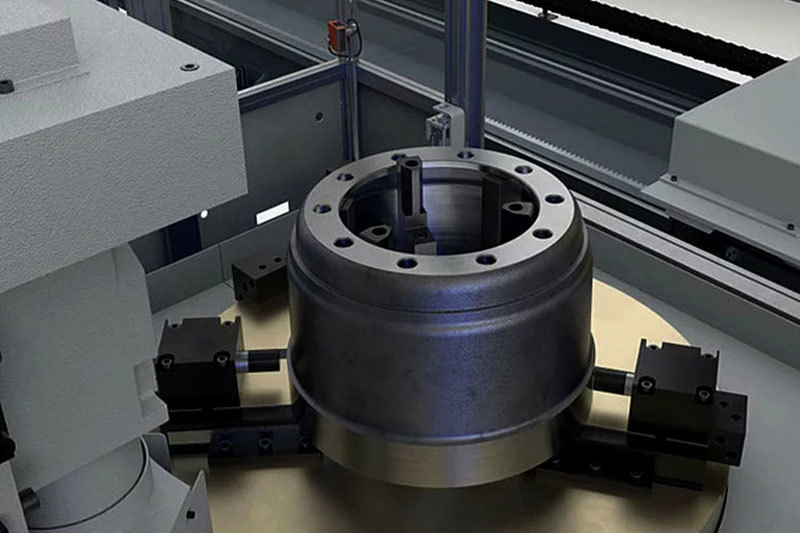

Truck brake drums are pivotal components in heavy-duty vehicle braking systems, playing a crucial role in ensuring safe and effective stopping power. As a professional in the automotive and parts industry, understanding the intricacies of brake drums can significantly enhance your service quality and customer satisfaction.

Brake drums function by using friction to slow down the vehicle. When the brake pedal is pressed, brake shoes are pushed against the inner surface of the drum, creating friction that slows the wheels. This design offers several advantages, such as excellent heat dissipation and a robust structure capable of withstanding heavy loads, making them ideal for trucks that often carry substantial weights.

Regular maintenance of truck brake drums is vital for optimal performance. Signs of wear, such as grooves or cracks on the drum's surface, can severely affect braking efficiency. Professionals should recommend routine inspections, focusing on checking the drum's diameter, surface condition, and alignment. It is also essential to monitor the brake shoes for wear, as uneven wear can lead to premature drum failure.

Another important aspect of truck brake drum maintenance is the proper installation and adjustment. Ensuring that the brake drums are fitted correctly is crucial for maintaining even wear on the brake shoes and achieving effective braking performance. It is advisable to follow manufacturer guidelines during installation to prevent issues that could arise from improper procedures.

Moreover, professionals in the automotive industry should stay informed about new technologies and advancements related to brake drums. Innovations such as lightweight composite materials and high-performance friction materials are becoming increasingly popular, offering improved durability and performance. Familiarizing yourself with these trends can help you provide informed recommendations to your customers, enhancing their overall experience.

In summary, truck brake drums are critical to the braking system's efficacy in heavy-duty vehicles. By understanding their function, maintenance requirements, and the latest technologies, professionals can better serve their customers, ensuring that vehicles remain safe and reliable on the road. Prioritizing education and keeping abreast of industry developments will not only enhance your knowledge but also establish your reputation as a trusted expert in the field.

Brake drums function by using friction to slow down the vehicle. When the brake pedal is pressed, brake shoes are pushed against the inner surface of the drum, creating friction that slows the wheels. This design offers several advantages, such as excellent heat dissipation and a robust structure capable of withstanding heavy loads, making them ideal for trucks that often carry substantial weights.

Regular maintenance of truck brake drums is vital for optimal performance. Signs of wear, such as grooves or cracks on the drum's surface, can severely affect braking efficiency. Professionals should recommend routine inspections, focusing on checking the drum's diameter, surface condition, and alignment. It is also essential to monitor the brake shoes for wear, as uneven wear can lead to premature drum failure.

Another important aspect of truck brake drum maintenance is the proper installation and adjustment. Ensuring that the brake drums are fitted correctly is crucial for maintaining even wear on the brake shoes and achieving effective braking performance. It is advisable to follow manufacturer guidelines during installation to prevent issues that could arise from improper procedures.

Moreover, professionals in the automotive industry should stay informed about new technologies and advancements related to brake drums. Innovations such as lightweight composite materials and high-performance friction materials are becoming increasingly popular, offering improved durability and performance. Familiarizing yourself with these trends can help you provide informed recommendations to your customers, enhancing their overall experience.

In summary, truck brake drums are critical to the braking system's efficacy in heavy-duty vehicles. By understanding their function, maintenance requirements, and the latest technologies, professionals can better serve their customers, ensuring that vehicles remain safe and reliable on the road. Prioritizing education and keeping abreast of industry developments will not only enhance your knowledge but also establish your reputation as a trusted expert in the field.

Tag:

Previous Page

All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

RELATED INFORMATION