Understanding the Critical Role of Brake Drums in Safe Towing with Semi Trailers

Release time:

21 Jul,2025

Understanding the Critical Role of Brake Drums in Safe Towing with Semi Trailers Towing a semi trailer involves a complex interplay of various vehicle components, each playing a crucial role in ensuring safety and performance. Among these components, **brake drums** stand out as vital elements that are often overlooked. In this article, we will delve into the anatomy and function of brake drums, t

Understanding the Critical Role of Brake Drums in Safe Towing with Semi Trailers

Towing a semi trailer involves a complex interplay of various vehicle components, each playing a crucial role in ensuring safety and performance. Among these components, **brake drums** stand out as vital elements that are often overlooked. In this article, we will delve into the anatomy and function of brake drums, their significance in towing applications, maintenance practices, and the best practices for ensuring safety while towing. With this knowledge, you will better understand how to maintain your braking system for safe and effective towing.

Table of Contents

- What Are Brake Drums?

- The Importance of Brake Drums in Towing

- How Brake Drums Function: A Detailed Look

- Materials Used in Brake Drum Manufacturing

- Signs of Worn Brake Drums

- Essential Maintenance Tips for Brake Drums

- When to Upgrade Your Brake Drums

- Safety Tips for Towing with Semi Trailers

- Frequently Asked Questions

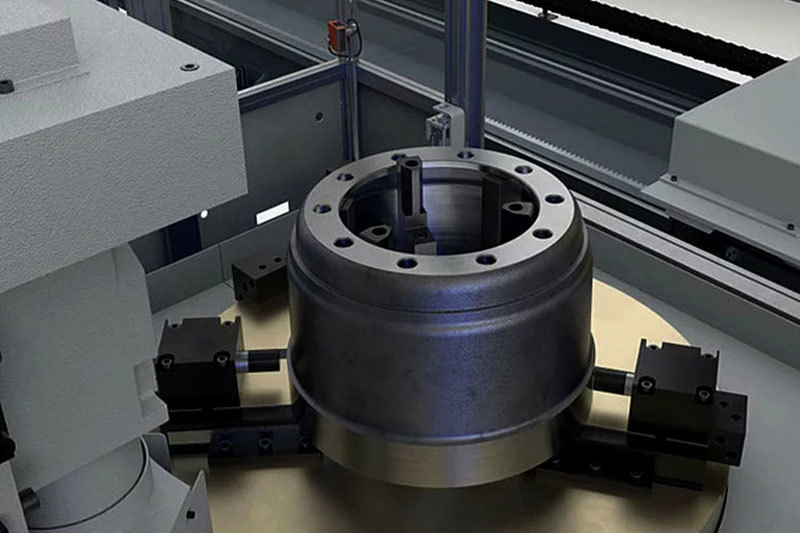

What Are Brake Drums?

**Brake drums** are circular components that house the braking mechanism in vehicle systems, particularly in heavy-duty applications like semi trailers. When a driver applies the brakes, brake shoes expand against the inner surface of the drum to create friction, which subsequently slows down or stops the vehicle. Understanding the mechanics of brake drums is essential for anyone involved in towing and maintaining heavy-duty vehicles.

The Importance of Brake Drums in Towing

When towing a semi trailer, brake drums play a crucial role in ensuring that the towed load can be managed safely. A properly functioning brake drum system can mean the difference between a safe stop and a disastrous accident, especially under high-stress conditions such as downhill descents or emergency stops. The effectiveness of the braking system directly impacts the overall safety and stability of the towing vehicle and its load.

Stability and Control

The braking system, particularly the brake drums, contributes significantly to vehicle stability. When a semi trailer is loaded, the braking distance can increase dramatically if brake drums are not functioning optimally. This can lead to **control issues** while maneuvering, potentially resulting in swaying or jackknifing. Thus, regular inspections and maintenance of brake drums are imperative for safe towing.

How Brake Drums Function: A Detailed Look

The operation of brake drums is a straightforward yet effective mechanism. When the brake pedal is pressed, hydraulic pressure is applied to the brake shoes, pushing them outward. The friction generated between the shoes and the drum slows the rotation of the wheel. This process is not just about stopping; it also involves the distribution of braking force, which is critical when towing.

The Role of Friction in Brake Performance

Friction is the heart of the braking process. The material of the brake shoes and the surface of the drum must be compatible to ensure maximum friction. Over time, wear and tear can change these materials' effectiveness, leading to decreased braking performance. Regular inspections can help identify wear early and mitigate risks associated with towing.

Materials Used in Brake Drum Manufacturing

Brake drums are typically made from materials like cast iron, aluminum, or composite materials. Each material has its advantages and applications:

- Cast Iron: Known for its durability and heat dissipation properties, cast iron is the most common material for heavy-duty brake drums.

- Aluminum: Lighter than cast iron, aluminum drums are often used in performance applications but may not withstand the same stress as cast iron.

- Composite Materials: These are increasingly being used for their lightweight and heat-resistant properties, providing a balance between performance and weight.

Signs of Worn Brake Drums

As brake drums age, they exhibit several signs of wear that should not be ignored. Recognizing these signs can help prevent accidents and maintain towing safety:

- Increased Stopping Distance: If you notice that your vehicle takes longer to stop, it may be time to inspect your brake drums.

- Vibrations or Pulsations: Unusual vibrations when braking can indicate uneven wear on the brake drums.

- Strange Noises: Grinding or squeaking sounds during braking often suggest that the brake shoes have worn down and are making contact with the drum material.

- Visible Cracks: Inspecting the brake drums visually can reveal cracks or warping, indicating a need for replacement.

Essential Maintenance Tips for Brake Drums

Maintaining brake drums is critical for safe towing. Here are some essential tips to keep your brake drums in optimal condition:

Regular Inspections

Conduct thorough inspections of your brake system at regular intervals, especially before long trips. Look for signs of wear and tear, and ensure that the brake shoes are in good condition.

Brake Adjustment

Ensure that the brake shoes are properly adjusted to maintain effective contact with the drum. Poorly adjusted brakes can lead to uneven wear and reduced braking efficiency.

Cleaning and Lubrication

Keep the brake drum area clean from debris and dirt. Regular cleaning can prevent contamination of the brake shoes and drums, enhancing their longevity. Lubricate moving parts as recommended to ensure smooth operation.

Replace Worn Components

If any components of the braking system are showing signs of wear, replace them immediately. This includes brake drums, shoes, and any associated hardware.

When to Upgrade Your Brake Drums

Upgrading your brake drums may be necessary for various reasons:

- Increased Load Requirements: If you frequently tow heavier loads, consider upgrading to high-performance brake drums that can handle the increased stress.

- Frequent Maintenance Imbalances: If you find yourself constantly repairing or replacing components, it may be a sign that your current drum setup is not suitable for your towing needs.

- Heat Dissipation Issues: If your brake drums are overheating, consider upgrading to materials with better heat dissipation properties.

Safety Tips for Towing with Semi Trailers

To ensure safe towing with semi trailers, consider the following safety tips:

Know Your Weight Limits

Always be aware of your vehicle's towing capacity and adhere to weight limits to maintain safe handling and braking performance.

Perform Pre-Tow Inspections

Inspect your vehicle and the semi trailer before towing. Check the brake system, tire pressure, and load distribution to ensure everything is in good condition.

Practice Defensive Driving

When towing, allow for greater stopping distances and avoid sudden maneuvers. Anticipate potential hazards and maintain a safe distance from other vehicles.

Frequently Asked Questions

1. How often should I inspect my brake drums?

It is advisable to inspect your brake drums at least every 10,000 miles or before long trips. Frequent inspections will help identify wear early on.

2. What are the signs that my brake drums need to be replaced?

Signs include increased stopping distance, vibrations, strange noises, and visible cracks. If you notice any of these, it’s time for a replacement.

3. Can I use brake drums from different manufacturers?

While it’s possible, it’s best to use brake drums that are compatible with your vehicle specifications. Mixing components can lead to inefficiencies and safety hazards.

4. Are there any performance benefits to upgrading brake drums?

Yes, high-performance brake drums can provide better heat dissipation, improved stopping power, and longer lifespan, making them beneficial for heavy-duty towing applications.

5. What’s the difference between drum brakes and disc brakes for towing?

Drum brakes are generally more effective for heavy loads because they provide greater surface area for friction. Disc brakes, however, can offer better performance in terms of heat dissipation and consistency.

Conclusion

Understanding the role of brake drums in towing with semi trailers is essential for maintaining safety and performance. Proper maintenance, routine inspections, and timely upgrades can significantly enhance your towing experience. By prioritizing the integrity of your braking system, you ensure not just your safety but also the safety of others on the road. As we’ve explored, brake drums are not merely components; they are a critical part of the towing ecosystem that requires attention and care. Stay informed, stay vigilant, and safe towing!

Tag:

Previous Page

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

RELATED INFORMATION