Understanding Trailer Brake Drums: Essential Insights for Performance and Safety

Release time:

16 Jul,2025

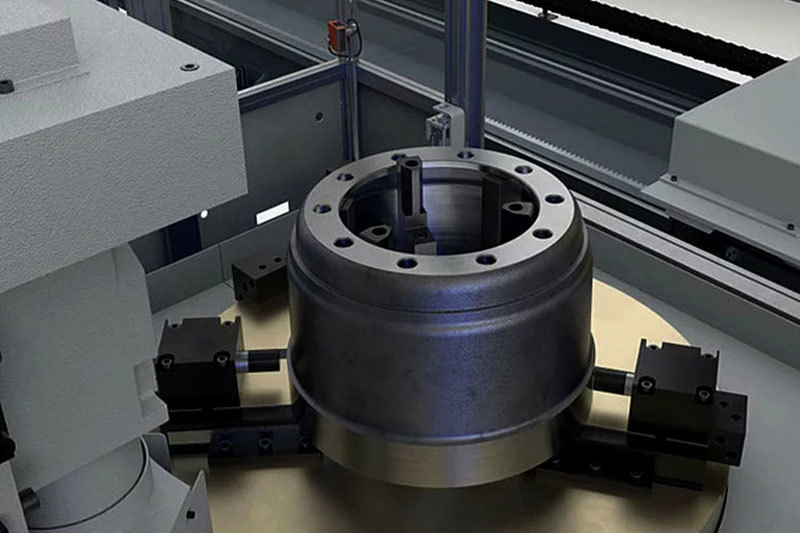

When it comes to trailer brake drums, understanding their functionality and maintenance is crucial for both safety and performance. Brake drums play an essential role in the braking system of trailers, providing the necessary friction to slow down or stop the vehicle when needed. These components are typically made from cast iron or aluminum and are designed to withstand significant wear and tear.

When it comes to trailer brake drums, understanding their functionality and maintenance is crucial for both safety and performance. Brake drums play an essential role in the braking system of trailers, providing the necessary friction to slow down or stop the vehicle when needed. These components are typically made from cast iron or aluminum and are designed to withstand significant wear and tear. Their primary function is to work in conjunction with brake shoes to generate the friction required to halt the trailer's movement.

One key element to consider when assessing trailer brake drums is their size and capacity. Different trailers have varying weight capacities, and the brake drums must be compatible to ensure effective braking performance. Choosing the correct size ensures that the brake system can handle the load and provides optimal stopping power, which is vital for both safety and vehicle longevity.

Maintenance of trailer brake drums is equally important. Regular inspections can help identify wear and tear before they become serious issues. Key points to check include the surface condition of the drums, the alignment of the brake shoes, and the overall functionality of the braking system. Signs of wear might include grooves or scoring on the drum surface, which can affect braking efficiency. If the drums show significant wear, they may need to be resurfaced or replaced to ensure safe operation.

Additionally, it is crucial to ensure that the brake system is properly adjusted. A well-adjusted brake system allows for even wear on the brake shoes and drums, prolonging the lifespan of these components. Misalignment can lead to uneven wear and reduced braking efficiency, which can pose serious safety risks.

When selecting trailer brake drums, it is essential to consider the specific requirements of your trailer type and the intended usage. Factors such as load capacity, frequency of use, and environmental conditions can influence the choice of the brake drum. For example, trailers used in heavy-duty applications may require more robust and durable brake drums compared to those used for light-duty tasks.

In conclusion, understanding the role of trailer brake drums is vital for ensuring the safety and performance of your trailer's braking system. Regular maintenance, appropriate sizing, and careful selection can greatly contribute to a reliable braking system, minimizing risks and enhancing overall vehicle performance. Whether for commercial or personal use, prioritizing the quality and condition of trailer brake drums is a key aspect of responsible trailer ownership.

One key element to consider when assessing trailer brake drums is their size and capacity. Different trailers have varying weight capacities, and the brake drums must be compatible to ensure effective braking performance. Choosing the correct size ensures that the brake system can handle the load and provides optimal stopping power, which is vital for both safety and vehicle longevity.

Maintenance of trailer brake drums is equally important. Regular inspections can help identify wear and tear before they become serious issues. Key points to check include the surface condition of the drums, the alignment of the brake shoes, and the overall functionality of the braking system. Signs of wear might include grooves or scoring on the drum surface, which can affect braking efficiency. If the drums show significant wear, they may need to be resurfaced or replaced to ensure safe operation.

Additionally, it is crucial to ensure that the brake system is properly adjusted. A well-adjusted brake system allows for even wear on the brake shoes and drums, prolonging the lifespan of these components. Misalignment can lead to uneven wear and reduced braking efficiency, which can pose serious safety risks.

When selecting trailer brake drums, it is essential to consider the specific requirements of your trailer type and the intended usage. Factors such as load capacity, frequency of use, and environmental conditions can influence the choice of the brake drum. For example, trailers used in heavy-duty applications may require more robust and durable brake drums compared to those used for light-duty tasks.

In conclusion, understanding the role of trailer brake drums is vital for ensuring the safety and performance of your trailer's braking system. Regular maintenance, appropriate sizing, and careful selection can greatly contribute to a reliable braking system, minimizing risks and enhancing overall vehicle performance. Whether for commercial or personal use, prioritizing the quality and condition of trailer brake drums is a key aspect of responsible trailer ownership.

Tag:

Previous Page

All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

RELATED INFORMATION