Breaking the Mold: Innovations in Brake Drum Manufacturing

Release time:

11 Jun,2025

Breaking the Mold: Innovations in Brake Drum Manufacturing Table of Contents Introduction to Brake Drum Innovations Historical Development of Brake Drums Revolutionary Materials in Brake Drum Manufacturing Advanced Manufacturing Techniques Sustainability in Brake Drum Production Performance Enhancements through Innovation Future Trends in Brake Drum Systems Conclusion FAQs about

Breaking the Mold: Innovations in Brake Drum Manufacturing

Table of Contents

- Introduction to Brake Drum Innovations

- Historical Development of Brake Drums

- Revolutionary Materials in Brake Drum Manufacturing

- Advanced Manufacturing Techniques

- Sustainability in Brake Drum Production

- Performance Enhancements through Innovation

- Future Trends in Brake Drum Systems

- Conclusion

- FAQs about Brake Drum Innovations

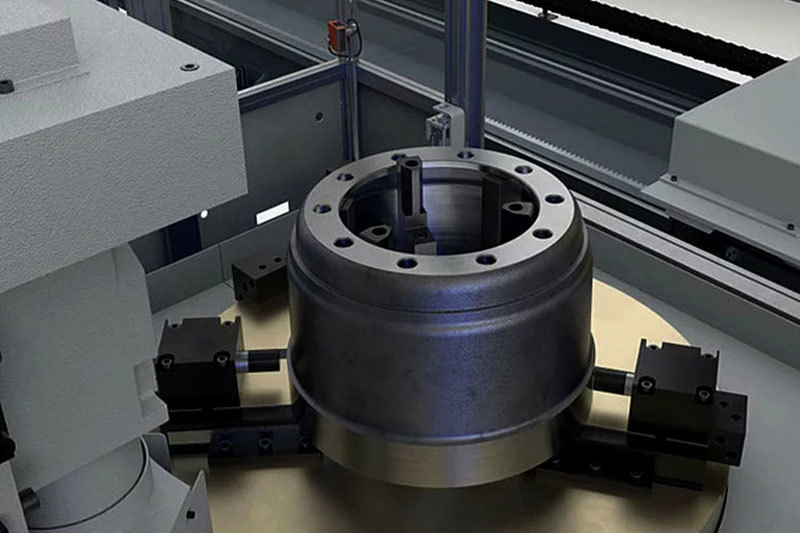

Introduction to Brake Drum Innovations

The brake drum is a critical component in the vehicle braking system, serving to slow down or stop a vehicle by converting kinetic energy into thermal energy through friction. With increasing demands for efficiency, performance, and safety, the automotive industry is witnessing a surge in innovations surrounding brake drum manufacturing. **This article explores the latest advancements** that promise to revolutionize this vital component, improving not only vehicle performance but also sustainability.

Historical Development of Brake Drums

Brake drums have been around since the early 1900s, evolving from simple, cast iron designs to more complex configurations. Initially, they were heavy and prone to wear, affecting vehicle safety. The introduction of **ventilated brake drums** in the 1960s marked a significant milestone, allowing for better heat dissipation and improved performance. As automotive technology progressed, the focus shifted towards harnessing new materials and technologies to enhance durability and efficiency in brake drum manufacturing.

Evolution of Design and Functionality

Each redesign aimed to address specific challenges, such as weight reduction without compromising strength. In recent years, manufacturers have increasingly turned to **computer-aided design (CAD)** and **finite element analysis (FEA)** to create more efficient components. These tools enable designers to simulate various conditions and optimize shapes, resulting in lighter and more effective brake drums.

Revolutionary Materials in Brake Drum Manufacturing

One of the most notable advancements in brake drum manufacturing is the introduction of innovative materials that enhance performance and reduce environmental impact.

Composite Materials

Composite materials, which combine plastics with fibers like carbon or aramid, are gaining traction in brake drum production. These materials offer lower weight and higher strength compared to traditional cast iron. As a result, vehicles equipped with composite brake drums demonstrate improved fuel efficiency and lower emissions.

Advanced Alloys

The development of **high-performance alloys** has also played a crucial role. Aluminum and magnesium alloys are now being employed not just for their lightweight properties but also for their superior heat resistance. This leads to longer lifespan and reduced brake fade during heavy usage.

Nanotechnology

Nanotechnology is emerging as a game-changer in material science. The incorporation of **nanoparticles** into brake drum material can significantly improve its mechanical properties, making it more resistant to wear and thermal degradation. This technology is still in its infancy but holds tremendous potential.

Advanced Manufacturing Techniques

Modern manufacturing techniques have transformed how brake drums are produced, leading to enhancements in quality and efficiency.

3D Printing

**3D printing**, or additive manufacturing, has opened new avenues in brake drum design. This technology allows for the creation of complex geometries that were previously impossible with traditional methods. It also reduces material waste and streamlines production processes.

Automated Assembly Lines

Automated assembly lines are improving production speed and consistency. With robots handling repetitive tasks, manufacturers can focus on quality control and innovation, ensuring that each brake drum meets high safety and performance standards.

Sustainability in Brake Drum Production

As environmental concerns become more pressing, the automotive industry is placing greater emphasis on sustainable practices.

Recyclable Materials

The shift towards using recyclable materials is helping manufacturers reduce their carbon footprint. By utilizing materials that can be recycled at the end of their lifecycle, companies are contributing to a circular economy, which minimizes waste.

Energy-Efficient Production Processes

**Energy-efficient production processes** are not just beneficial for the environment—they can also lead to significant cost savings. Manufacturers are investing in technologies that reduce energy consumption during the manufacturing process, thus lowering operational costs.

Performance Enhancements through Innovation

Innovative brake drum technologies are significantly enhancing vehicle performance.

Heat Management Systems

Effective heat management is crucial for brake performance. New designs incorporate **heat dissipation channels** that help manage the temperature during braking, reducing the risk of brake fade. This leads to more reliable braking performance under demanding conditions.

Improved Friction Materials

The development of advanced friction materials has made a significant impact on brake performance. These materials provide better grip and wear resistance, which translates to shorter stopping distances and enhanced safety.

Future Trends in Brake Drum Systems

Looking ahead, several trends are expected to shape the future of brake drum manufacturing.

Integration with Smart Technologies

The integration of **smart technologies** into brake systems is on the rise. Sensors that monitor performance in real-time can provide valuable data to drivers, alerting them to potential maintenance needs before they become critical issues.

Autonomous Vehicle Applications

As autonomous vehicles become mainstream, the braking systems will need to adapt to new technologies. This includes systems that can react faster than human drivers and incorporate advanced algorithms to enhance safety and performance.

Conclusion

The innovations in brake drum manufacturing are transforming the automotive industry, leading to safer, more efficient, and environmentally friendly vehicles. By embracing new materials, advanced manufacturing techniques, and sustainability practices, manufacturers are setting a new standard for performance and reliability. As we look to the future, ongoing advancements will continue to redefine what is possible in brake system design and functionality.

FAQs about Brake Drum Innovations

1. What materials are commonly used in modern brake drums?

Modern brake drums often utilize composite materials, advanced alloys, and even nanotechnology to enhance performance and reduce weight.

2. How does 3D printing impact brake drum manufacturing?

3D printing allows for complex designs, reduces material waste, and can expedite the production process, leading to higher quality brake drums.

3. Are there sustainable options for brake drum manufacturing?

Yes, many manufacturers are now using recyclable materials and implementing energy-efficient production processes to minimize their environmental impact.

4. What are the benefits of using advanced alloys in brake drums?

Advanced alloys provide superior heat resistance and lower weight, improving vehicle efficiency and performance.

5. How do innovations in brake drum technology improve vehicle safety?

Innovations like enhanced friction materials and heat management systems contribute to shorter stopping distances and more reliable braking, which significantly enhance overall vehicle safety.

Tag:

All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

RELATED INFORMATION