Why Brake Drums Are Crucial Components of Your Car's Braking System

Release time:

06 Apr,2025

Why Brake Drums Are Crucial Components of Your Car's Braking System In the intricate world of automotive engineering, every component plays a pivotal role in ensuring vehicle safety and functionality. Among these components, **brake drums** stand out as essential parts of the braking system. Understanding why brake drums are crucial can help car owners appreciate their importance and encourage pro

Why Brake Drums Are Crucial Components of Your Car's Braking System

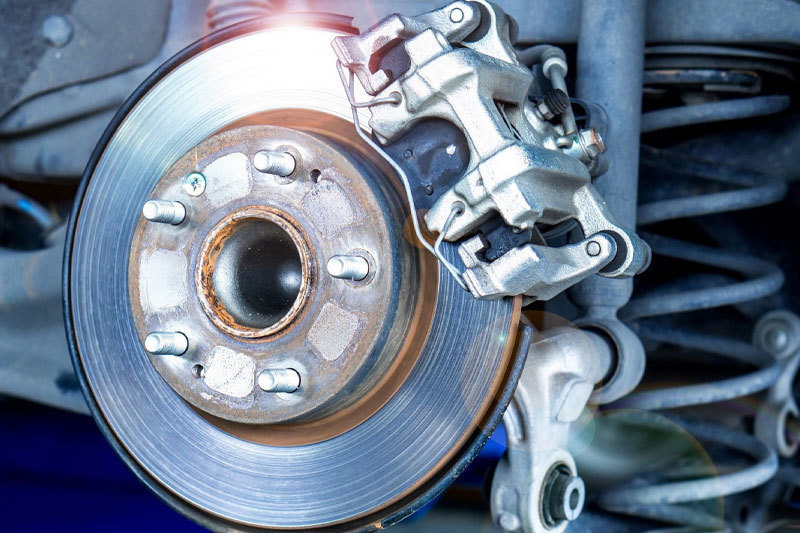

In the intricate world of automotive engineering, every component plays a pivotal role in ensuring vehicle safety and functionality. Among these components, **brake drums** stand out as essential parts of the braking system. Understanding why brake drums are crucial can help car owners appreciate their importance and encourage proactive maintenance. This article dives deep into their functionality, importance, and maintenance tips, ensuring that your vehicle remains safe and reliable.

Table of Contents

- The Role of Brake Drums in Automotive Safety

- Functionality of Brake Drums

- Types of Brake Drums

- Common Issues with Brake Drums

- Signs You Need to Replace Your Brake Drums

- Maintenance Tips for Brake Drums

- The Importance of Professional Inspection

- Frequently Asked Questions About Brake Drums

The Role of Brake Drums in Automotive Safety

Brake drums are integral to a vehicle's braking system, primarily found in **drum brake systems**. They play a vital role in ensuring that your car stops smoothly and efficiently. When you press the brake pedal, hydraulic pressure is generated, pushing the brake shoes against the inner surface of the brake drum. This friction is what ultimately slows down and stops the vehicle. Without well-functioning brake drums, your car's braking efficiency would be significantly compromised, leading to dangerous situations on the road.

Functionality of Brake Drums

The **functionality of brake drums** lies in their ability to convert kinetic energy into thermal energy through friction. The process can be broken down into the following steps:

The Stopping Mechanism

When the driver presses the brake pedal, hydraulic fluid is sent to the wheel cylinders, pushing the brake shoes outward. This action forces the shoes against the interior surface of the brake drum. The friction generated between the shoes and the drum slows down the wheel's rotation, ultimately bringing the vehicle to a stop.

Heat Dissipation

As the brake shoes create friction against the drum, heat is generated as a byproduct. Brake drums are designed to dissipate this heat efficiently, preventing overheating that could lead to brake fade. Maintaining proper heat management is essential to ensure effective braking.

Durability and Material Composition

Brake drums are typically made from cast iron or aluminum alloy, providing the durability needed to withstand constant use and high temperatures. Their robustness contributes to the overall longevity of the braking system, making it crucial for car owners to understand their maintenance.

Types of Brake Drums

Understanding the different types of brake drums can help car owners make informed decisions about their vehicles. The two primary types of brake drums are:

Standard Brake Drums

Standard brake drums are the most common type found in vehicles, characterized by their simple design and effective performance. They are typically used in combination with **drum brake systems** and are designed for everyday driving conditions.

Ventilated Brake Drums

Ventilated brake drums feature an internal airflow design that helps enhance cooling. These are often found in high-performance or heavy-duty vehicles where consistent braking performance is required, particularly under demanding conditions.

Common Issues with Brake Drums

Like any automotive component, brake drums can experience wear and tear over time. Here are some **common issues** associated with brake drums:

Cracks and Warping

Excessive heat can cause brake drums to warp or develop cracks, leading to uneven braking and potential safety hazards. Regular inspections can help identify these issues before they escalate.

Worn Brake Shoes

Worn brake shoes can lead to inadequate contact with the drum, resulting in decreased braking efficiency. It's essential to check both components regularly to ensure optimal performance.

Rust and Corrosion

Brake drums, especially those made from iron, are susceptible to rust and corrosion. This deterioration can compromise the integrity of the drum and should be addressed immediately.

Signs You Need to Replace Your Brake Drums

Identifying when to replace your brake drums can significantly impact your vehicle's safety. Watch for these **warning signs**:

Unusual Noises

If you notice grinding or squeaking noises when braking, it may indicate that your brake drums or shoes are worn and require replacement.

Longer Stopping Distances

Experiencing longer stopping distances than usual can signal that your brake drums are not functioning effectively and need immediate attention.

Vibrations When Braking

Feeling vibrations through the brake pedal can indicate warped brake drums. This issue should be addressed promptly to restore smooth braking performance.

Maintenance Tips for Brake Drums

Regular maintenance of your brake drums is essential for ensuring a safe driving experience. Here are some **helpful tips** to keep your brakes in top condition:

Regular Inspections

Schedule routine inspections of your braking system, including brake drums, at least once a year. This proactive approach allows for early detection of potential issues.

Brake Fluid Checks

Maintaining the proper level and quality of brake fluid is critical. Old or contaminated fluid can lead to decreased braking performance. Regularly check and replace brake fluid as needed.

Keeping Drums Clean

Cleaning the brake drums can help remove dust and debris that can hinder performance. Ensure that your brake components are free from contaminants to promote optimal function.

The Importance of Professional Inspection

While car owners can perform basic maintenance, professional inspection is crucial for ensuring comprehensive safety. Trained mechanics can offer insights into the condition of your brake drums and recommend necessary repairs or replacements. They possess the expertise to identify hidden issues that might not be apparent during a casual inspection.

Frequently Asked Questions About Brake Drums

1. How often should I replace my brake drums?

Brake drums should typically be inspected every 30,000 miles. Replacement depends on wear and tear, but they should be replaced if they show signs of damage or wear beyond manufacturer's specifications.

2. Can I drive with worn brake drums?

No, driving with worn or damaged brake drums can severely compromise your vehicle's braking ability, leading to dangerous situations. Immediate replacement is critical for safety.

3. What is the cost of replacing brake drums?

The cost of replacing brake drums varies based on the vehicle model and labor costs, but it typically ranges from $200 to $400 per axle, including parts and labor.

4. How can I tell if my brake drums are warped?

Symptoms of warped brake drums include vibrations during braking and unusual noises. A professional inspection is recommended to confirm warping.

5. Are there performance benefits to upgrading to ventilated brake drums?

Yes, upgrading to ventilated brake drums can improve heat dissipation and overall braking performance, especially for high-performance vehicles or those subject to heavy loads.

Conclusion

In summary, brake drums serve as critical components of your car's braking system, directly influencing driving safety and performance. Understanding their functionality, identifying potential issues, and adhering to regular maintenance can significantly enhance your vehicle's safety. By staying informed and proactive, car owners can ensure that their braking systems remain efficient and reliable, ultimately safeguarding both themselves and their passengers on the road. Prioritize the health of your brake drums and experience the peace of mind that comes with a well-maintained vehicle.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

RELATED INFORMATION